We offer products, solutions, and services across the entire installation of complete plants and production lines.

The construction of our feed industry and bulk handling machines, plants involve longer-term projects. Several years may pass between making an offer and the commencement of operation, since the plants designed and installed by us must ensure the operation of our clients for the next 15-20 years.

Designing is a prolonged process, during which we assess our client’s long-term development needs, what the products manufactured by it require, what it intends to manufacture and what quantity it wants to produce.

At the same time, we consult regarding what technological process used by us is the most favorable for our client.

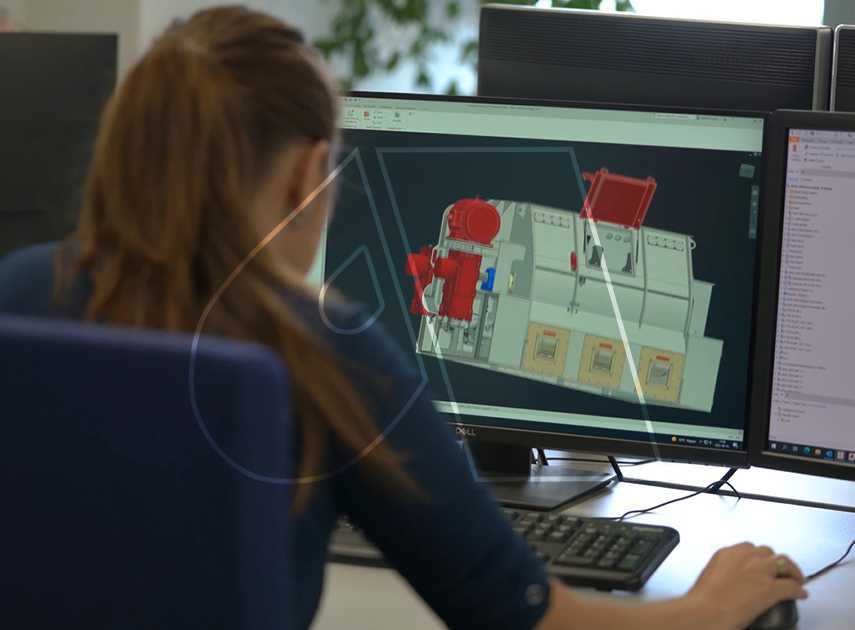

We provide an option for the assembly of almost completely automated plant units. Our design team uses the most up-to-date tools, such as 3D laser scanner surveying and 3D CAD design.

Our company devotes highlighted attention to continuous development, for the modernization of our instruments and related innovation.

During the construction of feed industry and bulk handling plant complexes, unexpected errors may arise at any point of the work process. During production, with the help of our experienced engineers and experts we react flexibly and quickly to arising problems.

We change the order according to the client’s requests, and since this is a long-term process we are able to integrate changes into the future plant defined by new customer requirements, even during the building phase. The plants constructed by us are steel frame structures in most of the cases.

We remain in constant contact with our clients even after the delivery, we provide maintenance and repair services as a separate contract, and also provide efficiency and technological developments.

The most dynamic business branch of our company is the manufacturing of feed industry and bulk handling plants and production lines. After the design works, preparation occurs next.

The technological equipment and machines comprising the plant are manufactured by our permanent expert staff in continuous consultation with our engineers. After complete construction and project management, we deliver the plant in a functional condition and in possession of all required operating licenses.

As a significant manufacturer of feed industry centerpiece machines we regard our role outstandingly important in the development of our region’s feed industry technology level.

Abraziv Ltd relies on a professional team that possesses outstandingly broad expertise and special experience in the business branch.

As a result of this, in the recent period our company has undergone a relatively dynamic growth phase. In the previous period our company usually worked on one large feed industry project each year, but currently multiple large projects are managed simultaneously.

Thanks to properly fostering our relationships and preserving our competitiveness, our company expanded its team with excellent professional staff members.

For the construction of a complex feed plant, precise logistical organization, accurate work, a combined installation team of experienced subcontractors are essential, which our company has retained for decades.

The manufacturing and design process is a complex task, therefore we ensure efficient operation even after delivery.

We feel that it is important to perform follow-up care of our finished installations, thus our company supports the smooth, uninterrupted, long-term and competitive operation of our partner plants with a competent service and spare parts background as well as a service contract.

This includes the periodic and occasional service and maintenance of pellet mills and expanders, the transport and renovation of chrome steel dies, the assembly of complete roller assemblies, replacement of the roller shell and bearings, as well as the comprehensive part supply of feed plant technologies.

For this appropriate transport is essential. Abraziv Ltd continuously expands its modern vehicle stock, which allows the simple, safe moving of tools and parts, their fixing and fast transport.

Abraziv Ltd constantly strives to achieve the maximum satisfaction of its clientele by manufacturing products and facilities that meet client expectations and applicable legal regulations.

Our company operates in accordance with a quality management system that satisfies the requirements of the MSZ EN ISO 9001:2015 standard, thereby ensuring regulation compliant and high quality level performance as well as the good market position of our company.